Unlocking Innovation: The Power of Rapid Prototype China for Metal Fabricators

The landscape of manufacturing is evolving faster than ever, with technological advancements reshaping how businesses operate. Among these innovations, rapid prototyping in China has emerged as a game-changer for metal fabricators, providing an agile solution to product development. In this comprehensive article, we will explore the multifaceted advantages of rapid prototyping, its applications in the metal fabrication industry, and how Chinese manufacturers are leading this revolution.

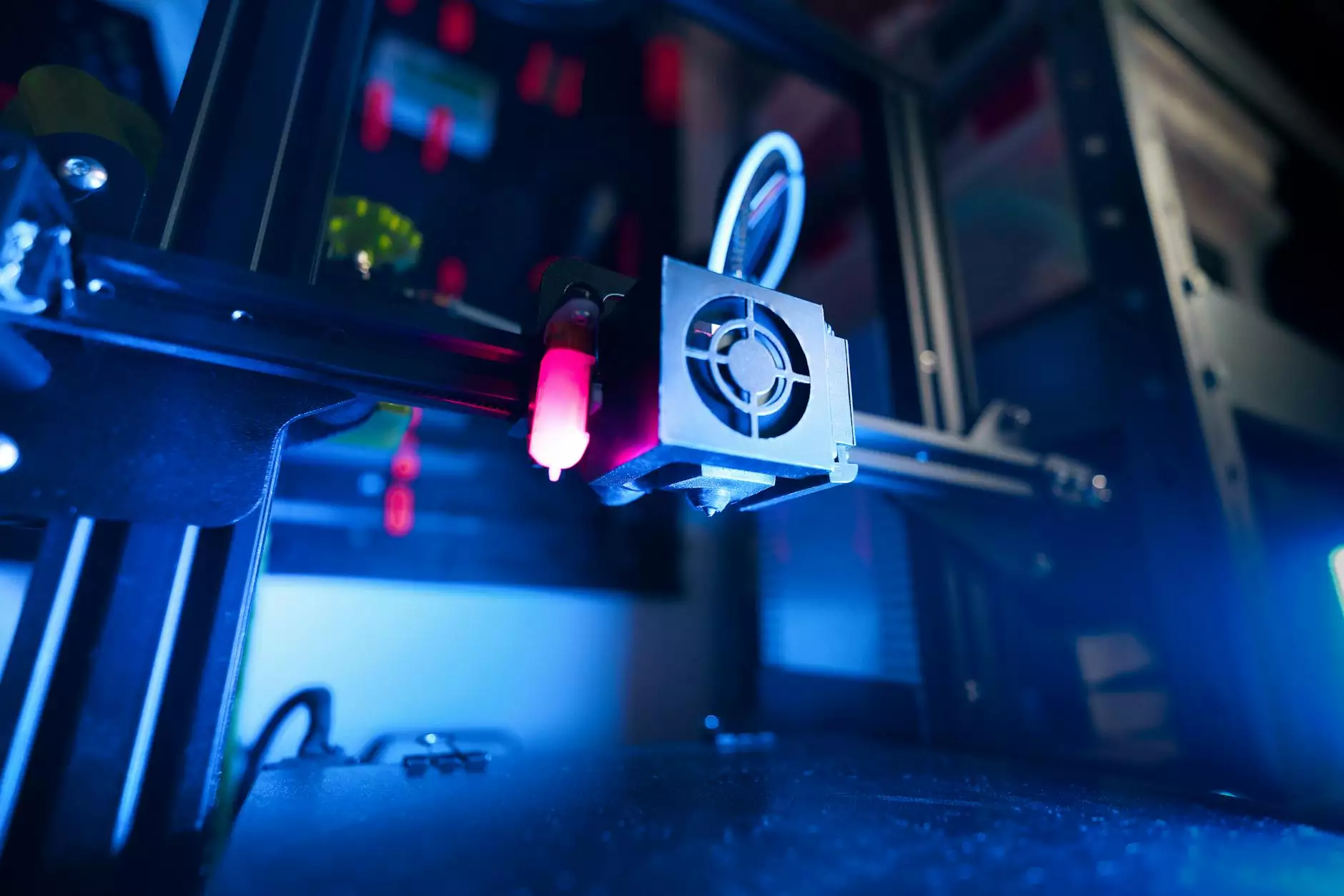

Understanding Rapid Prototyping

Rapid prototyping is a method that allows for the quick fabrication of a physical part or assembly using 3D computer-aided design (CAD) data. The process offers a plethora of benefits, including:

- Speed: Rapid prototyping significantly reduces the time from concept to production.

- Cost-Effectiveness: It lowers the costs associated with traditional prototype development methods.

- Enhanced Collaboration: It fosters better communication among teams by providing a tangible representation of ideas.

- Increased Flexibility: Designers can make iterative changes quickly, optimizing the product before mass production.

Why Choose China for Rapid Prototyping?

When it comes to rapid prototyping, China stands out as a global leader due to various factors:

1. Advanced Technology & Expertise

The country has invested heavily in state-of-the-art manufacturing technologies. Chinese firms utilize 3D printing, CNC machining, and laser cutting techniques that significantly enhance the quality of prototypes. By leveraging cutting-edge technology, manufacturers in China can produce highly precise and intricate designs that meet demanding specifications.

2. Cost Advantages

Cost is a major factor for businesses when considering manufacturing options. Rapid prototype China offers lower labor and material costs without compromising quality. Businesses can reduce their overall production expenses, allowing for greater investment in research and development.

3. Scalability

Chinese manufacturers are well-equipped to scale production. Once a prototype is finalized, they can transition quickly to large-scale manufacturing, streamlining the overall product development lifecycle. This capability is essential for businesses looking to capture market opportunities swiftly.

4. Rich Supplier Ecosystem

China hosts a vast network of suppliers and manufacturers that specialize in various aspects of metal fabrication and prototyping. This ecosystem enables companies to source materials and services efficiently, ensuring high-quality outcomes for their projects.

Applications of Rapid Prototyping in Metal Fabrication

In the metal fabrication industry, rapid prototyping has transformative applications, including:

1. Product Development

The ability to design and test prototypes rapidly allows metal fabricators to innovate continuously. Whether creating components for automotive, aerospace, or consumer products, rapid prototyping enables designers to validate concepts early in the development process, reducing the risk of costly mistakes.

2. Functional Testing

Prototypes can be used to conduct functional tests, ensuring that products meet specifications and operate correctly. This testing phase identifies issues that can be addressed before moving to full-scale production, enhancing product reliability and performance.

3. Custom Parts Production

Fabricators can create customized parts tailored to specific needs, facilitating innovation in sectors that require unique solutions. This flexibility allows for adjustments based on client feedback, effectively integrating user preferences into the design process.

4. Short-Run Production

For metal fabricators, short-run production capabilities are vital for responding to market demands swiftly. Rapid prototyping enables them to fill niche markets with limited runs without the need for extensive investment in tooling or machinery.

Case Studies: Successful Implementations of Rapid Prototyping in China

Case Study 1: Automotive Component Development

Several automotive companies have leveraged rapid prototyping in China to reduce their time-to-market. By creating prototypes of new components, they can test performance and fit with existing systems before full production. This approach has led to significant savings in both time and development costs.

Case Study 2: Aerospace Engineering

In aerospace, precision is paramount. Chinese metal fabricators harness the power of rapid prototyping to create highly detailed components for aircraft. The ability to iterate designs quickly ensures that safety and performance standards are met consistently, leading to enhanced aircraft reliability.

Case Study 3: Consumer Electronics Innovation

Consumer electronics companies use rapid prototyping to bring innovative products to market faster. In a sector driven by trends, the ability to design, prototype, test, and launch new products rapidly is critical to maintaining competitive advantage. China's robust prototyping services help these companies keep pace with consumer demands.

Challenges and Considerations in Rapid Prototyping

While the benefits of rapid prototyping in China are substantial, there are challenges to consider:

1. Quality Control

Ensuring consistent quality across all prototypes is crucial. Businesses must implement robust quality control measures to verify that their prototypes meet desired specifications and tolerances.

2. Communication Barriers

Effective communication with overseas manufacturers is vital. Language differences and distance can sometimes lead to misunderstandings. Utilizing professional project management tools and clear, detailed documentation can mitigate these risks.

3. Intellectual Property Concerns

Protecting intellectual property (IP) while working with external manufacturers is essential. Companies should establish non-disclosure agreements and work with reputable firms that respect IP rights to avoid potential infringements.

Future Trends in Rapid Prototyping

The future of rapid prototyping is bright, with several emerging trends shaping its landscape:

1. Integration of AI and Automation

Artificial intelligence (AI) and automation technologies are set to revolutionize the rapid prototyping process. AI can optimize design and production methods, while automation can speed up the manufacturing process, reducing lead times even further.

2. Enhanced Materials

New materials that allow for greater durability, strength, and design flexibility are constantly being developed. Advances in materials science will expand the possibilities of rapid prototyping, enabling more complex designs than ever before.

3. Sustainability Initiatives

With increasing pressure on manufacturers to adopt sustainable practices, the industry is moving towards more eco-friendly materials and production methods. Rapid prototyping can play a crucial role in minimizing waste and optimizing material usage.

4. Expansion of Educational Resources

As the need for skilled professionals in rapid prototyping rises, educational institutions are beginning to incorporate relevant training and courses. This expansion will ensure a steady pipeline of talent to support the industry’s growth.

Conclusion

In conclusion, the advantages of rapid prototyping in China are clear. For metal fabricators seeking to enhance their product development processes, China offers a unique combination of advanced technology, cost savings, and scalability. By embracing rapid prototyping, businesses can foster innovation, improve product quality, and accelerate their time-to-market, ultimately gaining a competitive edge in today’s fast-paced manufacturing environment. As the industry continues to evolve, those who invest in rapid prototyping will undoubtedly lead the charge toward a more efficient and innovative future.

Visit DeepMould.net to learn more about how your business can benefit from rapid prototyping and high-quality metal fabrication solutions.